أخبار

يستكشف

Transitioning from paper-based options to digital solutions is a crucial step for many industries, including mining. Traditional methods, such as handwritten logbooks and reports, are prone to errors, inefficiencies, and loss of critical information. Digital solutions such as Magman and Simbio offer significant benefits in speed, ease of use, and cost savings. K ey Benefits of Digital Solutions Speed and Efficiency Faster completion of inspections and data collection. Instant information sharing via internet connections. Reduced time for data entry and reporting. Real-time access to reports for all necessary personnel. Ease of Use Efficient and accurate data collection with mobile apps and IoT devices. Simplified processes using barcode scanning, RFID, and standardized forms. Automatic organization and storage of information for historical records and audit trails. Customization Tailored solutions to fit specific business needs and processes. Customizable checklists, forms, and corrective actions. Flexible hosting options (in-house servers or cloud-based solutions). Integration with existing systems and workflows. Cost Savings Elimination of paper and postage expenses. Platforms like Magman and Simbio deliver significant savings per document, including productivity and revenue gains. Substantial cumulative savings when multiplied by thousands or millions of documents annually. Environmental Benefits Reduced paper usage saves trees and decreases carbon emissions. Steps to Successful Digital Transformation Assess Organizational Needs Identify specific requirements and challenges. Determine essential features and capabilities in a digital solution. Select the Right Provider Choose providers offering comprehensive, customizable solutions. Ensure the system can be tailored to business size and scale. Evaluate the benefits of increased proficiency through speed and customization. Invest in Training and Education Provide training to help workers adapt to new technologies. Highlight the importance of digital tools in improving safety and efficiency. Embracing digital solutions is essential for mining operations to stay competitive, efficient, and environmentally responsible. The transition from paper-based to digital systems enables better data management, faster decision-making, and enhanced safety. By focusing on speed, customization, cost savings, and proper training, organizations can successfully transition to a paperless environment. Leveraging technology not only improves operational efficiency but also contributes positively to the environment. For those interested in going paperless, applications like the Magman and Simbio suite provide valuable operational insight and real-world practicality to support this transition.

Magman Stocktake New Features Stocktake compliance and balancing your magazine is a key regulatory requirement. Magman has always been focused on this through proactive alerting and email notifications. This has now been improved further by introducing a new stocktake validation workflow. This workflow prevents other transactions occurring if the magazine does not balance and requires approval via designated persons to proceed past an imbalanced magazine. The updated Magman system ensures seamless regulatory compliance and reduced downtime by enforcing users to complete a stocktake each shift prior to any other magazine transactions, removing any guesswork or administration level controls in the stock validation process and immediately requiring intervention if it does not balance. Here’s the new Magman stocktake workflow:

In the bustling ecosystem of the mining industry, where efficiency and innovation are paramount, Digital Terrain's flagship product, Simbio, stands as the embodiment of synergy and harmony. Just as flowers and bees, or clownfish and anemones, thrive through their symbiotic relationships, Simbio brings together the diverse elements of Digital Terrain's portfolio to create a seamless, integrated solution that transforms the way mining operations are managed and executed. The Power of Symbiosis: Uniting Strengths for Unparalleled Success At its core, Simbio is about the interconnectedness of all components within the Digital Terrain suite. This revolutionary product combines the strengths of PLAN, MANAGE, PLOD, Magman, IoT, Digitisation Services, and Integration Solutions, forging a unified platform that enhances every aspect of mining operations. Just as bees and flowers depend on each other for survival and growth, each element within Simbio works in perfect harmony, ensuring that data flows seamlessly, operations run smoothly, and productivity reaches new heights. PLAN: The Blueprint for Success Every great endeavor begins with a plan, and in the mining world, precision planning is the cornerstone of success. Simbio’s PLAN module is the architect of operational excellence, providing detailed blueprints that guide every phase of the mining process. With real-time data access and sophisticated analytics, PLAN ensures that every decision is informed, every action is deliberate, and every outcome is optimized. It’s not just planning; it’s orchestrating a symphony of success. MANAGE: The Conductor of Operations Once the blueprint is set, the MANAGE module takes the baton, conducting the day-to-day operations with unmatched efficiency. MANAGE brings clarity and control, allowing operators to oversee every facet of the mining process in real-time. It’s the heartbeat of the operation, ensuring that everything runs in perfect rhythm, much like the harmonious relationship between clownfish and anemones, where each supports the other to thrive in their shared environment. PLOD: Precision and Performance In the fast-paced world of mining, precision and performance are paramount. The PLOD module of Simbio delivers just that, providing real-time tracking and reporting of on-site activities. It ensures that every action is recorded, every movement is monitored, and every task is executed with pinpoint accuracy. PLOD is the watchful eye that guarantees safety, boosts productivity, and drives the operation towards its goals. Magman: Mastering the Flow of Resources Resource management is the lifeblood of any mining operation, and Magman is the master of this domain within Simbio. It optimizes the allocation and utilization of resources, ensuring that every asset is used to its fullest potential. Magman is the keystone species in the Simbio ecosystem, balancing supply and demand, much like bees pollinate flowers to ensure the continuity of their symbiotic relationship. IoT: The Pulse of Innovation In the age of digital transformation, the Internet of Things (IoT) is the pulse that keeps the Simbio ecosystem alive. IoT integration within Simbio connects every piece of equipment, every sensor, and every data point, creating a network of intelligence that drives smart decision-making. It’s the neural network of the operation, sensing, communicating, and responding to the dynamic needs of the mining environment. Digitisation Services and Integration Solutions: The Backbone of Connectivity At the heart of Simbio’s success is its robust Digitisation Services and Integration Solutions. These elements ensure that all data is seamlessly integrated, all systems are connected, and all processes are digitized for maximum efficiency. It’s the foundation that supports the entire ecosystem, much like the interconnected roots of a forest that share nutrients and resources, ensuring the health and vitality of every tree. The Future of Mining: A Symbiotic Vision Simbio is more than just a product; it’s a vision for the future of mining. It represents the pinnacle of innovation, the epitome of efficiency, and the zenith of productivity. By harnessing the power of symbiosis, Digital Terrain has created a solution that not only meets the needs of today’s mining operations but also anticipates the challenges of tomorrow. Conclusion: Thriving Together In the grand tapestry of the mining industry, where every thread must be perfectly woven to create a masterpiece, Simbio stands as the ultimate tool for achieving symbiotic success. Just as flowers and bees, and clownfish and anemones, thrive through their interdependence, so too does the Digital Terrain portfolio, united under the banner of Simbio. Together, we are not just surviving; we are thriving, reaching new heights, and setting the gold standard for the industry. With Simbio, the future of mining is not just bright; it’s brilliant.

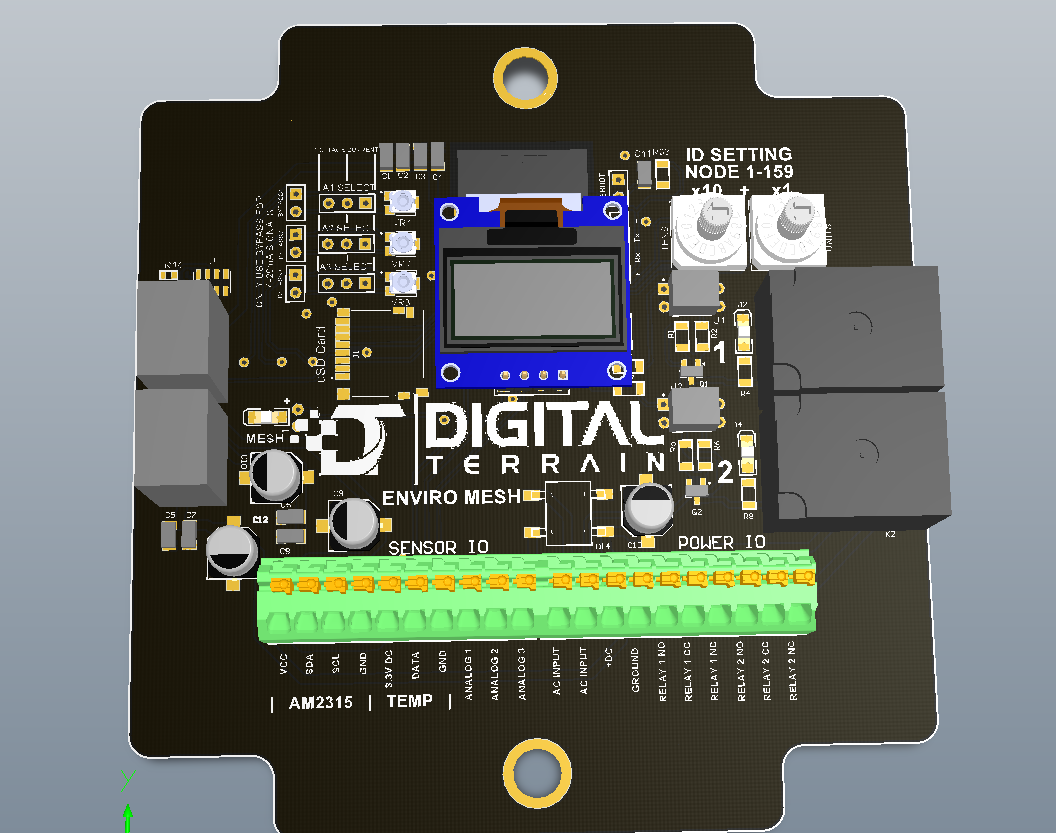

Digital Terrain Founder and CEO Andrew Rouse and Roobuck Director and General Manager Henry Gong are excited to announce they have signed a collaborative partnership which will allow for direct device level technology integration, not just in the cloud. Digital Terrain is now a reseller for Roobuck technology and hardware and aims to incorporate this into their Simbio stack of Products to add further value to their client base through a number of collaborative initiatives. The first point of integration is with their Simbio tablets and the Roobuck Smart Cordless cap lamp. Founder and CEO Andrew Rouse comments “As the technology available continues to improve and change, it is important that we collaborate with like-minded companies to improve our speed of delivery and focus on value for our customers. This is achieved with trust and a great relationship between companies so that our teams can come together openly and honestly to deliver real value. Integrating on a device-to-device level enables our end users to receive timely information when it matters, not at the end of the shift, or never at all enabling true change and improvement. We are excited to collaborate with Roobuck on this journey” The Roobuck Cordless Cap lamp comes equipped with Wi-Fi/BLE/RFID/NFC and an inbuilt IMU. Their latest model is also Intrinsically safe, meaning the technology can be used in underground coal mines. The Simbio solution is already in use in underground coal in addition to their larger presence in underground hardrock. Device level integration is unique and enables key personnel to understand and make decisions when it matters Both companies are enabling the devices to communicate with each other. A simple use case is when the Simbio device receives a message and depending on its urgency highlighted, proceeds to flash the cap lamp, alerting the operator there is a message. The flashes range from rapid ones to highlight an immediate response to a casual few flashes to say there is something there to look at when time becomes available. This enables yet another touch point to the workforce to ensure their safety is paramount. They also have the ability to assist in confirming locations of personnel. For example we can improve the confidence that a person is in a particular area if a number of devices are enabled and assigned to them. Unforeseen events to an operator wearing the cap lamp, which can be identified via a button triggered duress call or automatically recorded via IMU movement detection, could send a message to the tablet to alert others of someone needing to come and check on their welfare. “We are looking forward to working with the Digital Terrain teams to identify use cases whereby having both devices communicating can improve safety, reduce downtime or increase productivity” mentions Dane Zielinski-Nicolson, CTO for Roobuck. About Roobuck Roobuck is a leading provider of Mine IoT Solutions and Devices, Cap Lamps, Safety Lights, and other Explosion-proof Products. Its products are recognised throughout the industry as a cost-effective, high-quality solution which can be adapted to any site specific requirement. For more information visit: https://www.roobuck.com.au/ About Digital Terrain Digital Terrain is a Mining focussed technology business who can rapidly deploy their solution to realise immediate benefits to the workforce and improve timeliness of data. They provide the Simbio Suite of products including Magman explosives management and a number of OT devices. We are proudly the first in the world in 2016 to implement a large scale handheld device solution underground, working offline or on-line across multiple locations and continue to improve it every day. We track all mining processes, not some, making it a universal system for your operation.\ The unique selling point is our system came from mining, real world, multi-site and change management processes. The back-end data model of Simbio is over 15 years mature, eliminating teams of people to establish and configure a new system. Our solutions are offered not just as a blank database, it is a system already setup and ready to configure, we can go paperless from day one! Contact Shaun Brennan for any questions, or service information. Shaun.Brennan@digitalterrain.io

Privacy Policy Digital Terrain Pty Ltd built the Simbio Magman app as a Free app. This App is provided by Digital Terrain Pty Ltd at no cost and is intended for use as is.The app requires a connection to the Simbio Magman main system, and is obtained by a licencing agreement with Digital Terrain. This page is used to inform visitors regarding our policies with the collection, use, and disclosure of Personal Information if anyone decided to use our App. If you choose to use our App, then you agree to the collection and use of information in relation to this policy. The Personal Information that we collect is used for providing and improving the App. We will not use or share your information with anyone except as described in this Privacy Policy. The terms used in this Privacy Policy have the same meanings as in our Terms and Conditions, which is accessible at Simbio Magman unless otherwise defined in this Privacy Policy. Information Collection and Use For a better experience, while using our app, we may require you to provide us with certain identifiable information, including :- Location Information - is utilised by the application to provide context sensitive data to users. It also location stamps tasks that users request to undertake. Background location is enabled to ensure that when other applications are being used, Magman still has access to location information when performing background data synchronization operations, Network Information - is required so the app can determine if a network connection is available, and the type of network access (e.g. WiFi, 3G/4G/5G, etc) Battery Information - so we can let you know how your tablet is going, Bluetooth - so we can detect bluetooth devices, Camera - so you can take photos of work, and report issues. Log Data We want to inform you that whenever you use our App, in a case of an error in the app we collect data and information (through third party products) on your phone called Log Data. This Log Data may include information such as your device Internet Protocol (“IP”) address, device name, operating system version, the configuration of the app when utilizing our App, the time and date of your use of the App, and other statistics. Cookies Cookies are files with a small amount of data that are commonly used as anonymous unique identifiers. These are sent to your browser from the websites that you visit and are stored on your device's internal memory. This Service does not use these “cookies” explicitly. However, the app may use third party code and libraries that use “cookies” to collect information and improve their services. You have the option to either accept or refuse these cookies and know when a cookie is being sent to your device. If you choose to refuse our cookies, you may not be able to use some portions of this App. Service Providers We may employ third-party companies and individuals due to the following reasons: * To facilitate our Service; * To provide the Service on our behalf; * To perform Service-related services; or * To assist us in analyzing how our Service is used. We want to inform users of this Service that these third parties have access to your Personal Information. The reason is to perform the tasks assigned to them on our behalf. However, they are obligated not to disclose or use the information for any other purpose. Security We value your trust in providing us your Personal Information, thus we are striving to use commercially acceptable means of protecting it. But remember that no method of transmission over the internet, or method of electronic storage is 100% secure and reliable, and we cannot guarantee its absolute security. Links to Other Sites This App may contain links to other sites. If you click on a third-party link, you will be directed to that site. Note that these external sites are not operated by us. Therefore, we strongly advise you to review the Privacy Policy of these websites. We have no control over and assume no responsibility for the content, privacy policies, or practices of any third-party sites or services. Children’s Privacy These Services do not address anyone under the age of 13. We do not knowingly collect personally identifiable information from children under 13 years of age. In the case we discover that a child under 13 has provided us with personal information, we immediately delete this from our servers. If you are a parent or guardian and you are aware that your child has provided us with personal information, please contact us so that we will be able to do necessary actions. Changes to This Privacy Policy We may update our Privacy Policy from time to time. Thus, you are advised to review this page periodically for any changes. We will notify you of any changes by posting the new Privacy Policy on this page. This policy is effective as of 2024-09-01 Contact Us If you have any questions or suggestions about our Privacy Policy, do not hesitate to contact us at hello@digitalterrain.io.

Digital Terrain Founder and CEO, Andrew Rouse and NAUTITECH® CEO, Mac Powolny, are excited to announce a partnership which will integrate technologies from both companies to bring communications and connectivity to Hardrock Mining and Tunneling in Australia and New Zealand. As distributor of the NAUTITECH® Spitfire® Broadband Powerline Modem (BPLM), Digital Terrain will leverage their firsthand mining expertise and experience to provide access to real-time data, productivity analysis, voice and video in complex Hardrock environments and tunneling projects. With global patents and a decades-long proven track record in underground Softrock mining worldwide, the Spitfire® BPLM is optimally suited to drive safety, productivity and profitability outcomes in Hardrock. “We are excited to begin our collaboration with NAUTITECH® on providing connectivity and visibility in situations that are hard to reach. Our products are complimentary to each other with the aim of “lifting the lid” on the underground” states Andrew Rouse, CEO and Founder of Digital Terrain. Mac Powolny, CEO of NAUTITECH® continues to add “There are a substantial number of synergies and learnings both companies can achieve by working together. Successful collaboration is a win-win situation and I am confident the teams at NAUTITECH® and Digital Terrain will work together to solve many problems for our joint customer base” Contact Shaun Brennan for any questions, or service information. Shaun.Brennan@digitalterrain.io

Monitoring rock bolts, reinforcement of a decline, and drift in underground mining is crucial for ensuring the safety and stability of mine workings. Well-established benefits and legal requirements associated with this practice include: 1. Safety Assurance: Regular monitoring of rock bolts and reinforcement ensures that the underground workings remain stable, minimising the risk of roof falls, collapses, and other hazardous incidents. 2. Early Detection of Instabilities: Monitoring allows for the early detection of any signs of instability or degradation in the rock mass or support systems, enabling proactive measures to be taken to address potential issues before they escalate. 3. Compliance: Compliance with legal regulations and safety standards is crucial in the mining industry. Regular monitoring helps ensure that the mine operator is meeting all relevant regulatory requirements, reducing the risk of fines or legal liabilities. 4. Mining Codes and Guidelines: Many jurisdictions have specific mining codes or guidelines that outline the requirements for monitoring and maintaining underground mine workings. These codes may specify the frequency of inspections, the methods to be used, and the criteria for assessing the condition of rock bolts and reinforcement. 5. Industry Best Practices: In addition to legal requirements, mining companies adopt industry best practices and standards developed by organisations such as the International Society for Rock Mechanics (ISRM) or the Mine Regulators in each state across Australia. These guidelines provide recommendations for monitoring techniques and frequencies to ensure the safety and stability of underground workings. With a strong background in Mining, Digital Terrain appreciates the importance of monitoring rock bolts and reinforcement in underground mining for mine operators and owners. Our Lidar Mapping services enable clients to observe relevant regulations, codes, and industry best practices resulting in enhanced safety and stability of underground mine workings. Digital Terrain Digital Terrain have solutions that replace or augment existing capabilities for capturing, processing, analysis,and reporting. We also offer onsite instruction and training where customers seek to build their own expertise. Enjoy the sample video of our capabilities and contact David Juany for any comments, questions, or service information. david.Jaunay@digitalterrain.io or +61434317580