Regulated Materials

Magman

General Overview

Magman solves problems that are typical of paper based explosives magazine processes through its unique design. The software has been specially designed to:

- Complete automatic math for users

- Provide a fully contained solution requiring no additional transcription

- Automatically always report stock levels

- Have a clear audit trail

- Enforce data quality and accountability

- Meet the needs of mining operators, supervisors, administrators and engineers

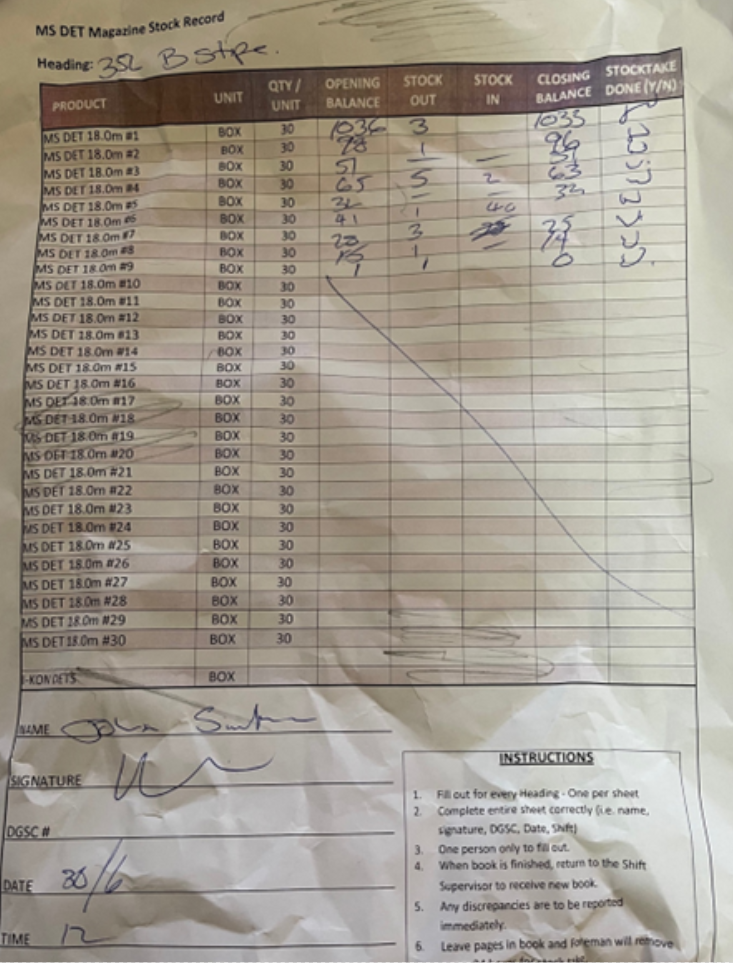

The problem with paper

The problem with paper in a explosives magazine context is that meeting compliance is time consuming and diffiicult. Unlike normal stock interactions, when errors occur with regulated materials (especially explosives) there are significant cost, reporting and compliance implications. Even simple errors can have significant consquences.

- Mathematical mistakes when calculating stock levels are wasy to make

- Ambiguous handwriting and misinterpretation of written data is problematic

- Transcription of errors into other systems involves heavy rework as information is propogated through other systems

- Delayed stock level reporting is more than just inconvienient

- Backtracking for compliance or reconciliation purposes is time consuming, manual and painstaking especially when dealing with stock that is constantly moving to keep the mine operational.

- Data quality and consistency is not enforcable

- No data accountability

- Auditability and accountasbility lines become blurred

Software Overview

Magman solves paper based problems with software that has been specially designed to:

- Complete automatic math for users

- Provide a fully contained solution requiring no additional transcription

- Automatically always report stock levels

- Have a clear audit trail

- Enforce data quality and accountability

- Meet the needs of mining operators, supervisors, administrators and engineers

Tablet Overview

Intrinsically Safe TabletsA key part of the Magman solution is the custom hardware specifically designed for the explosive solution.

The Australian standards for explosives, AS2187.2 -12.1.1 - Single Source Safe Distances for Electric Detonators Subject to Radio Frequency Radiation, outlines key distances between radio frequency (RF) emitting devices and Type 2 Instantaneous Electric Detonators, or the typical mining electric det used for initiation.

To solve this problem Magman utilises the most effective level in the hierarchy of controls – Elimination. Through collaboration with Getac, Magman exclusively has a range of tablets with all RF producing components physically removed from the device.

Governance management & automatic alerts

A core reason to utilise a digital system is the automated governance and compliance assistance that can be provided.

Magman provides automated reporting to ensure magazine’s remain complaint, starting from notifications during stocktakes on incorrect counts to the end user, and escalating through automatic emails to mine staff that a discrepancy has occurred.

This ensures that key personnel are always up to date with magazine compliance even without manually checking the system.

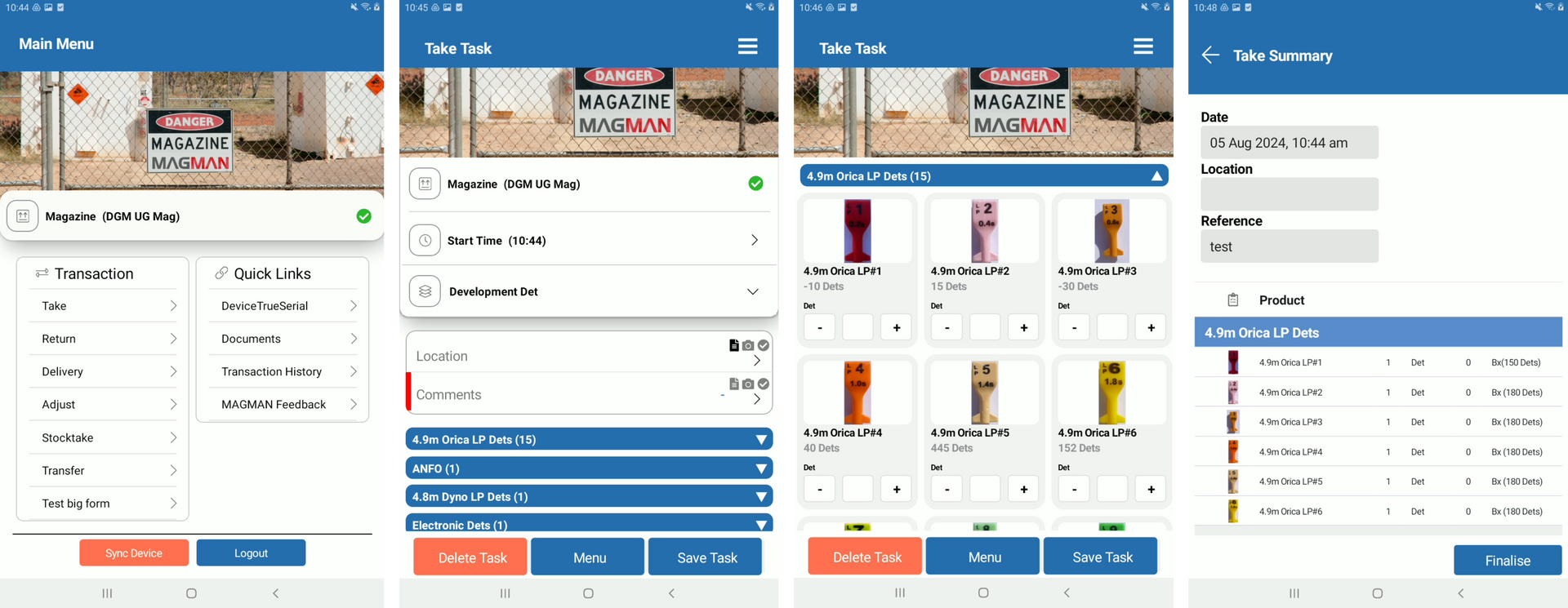

Tablet Interface

Magman’s tabet application contains all the functions any user needs to execute transactions within an explosives magazine. Recording a clear audit trail of what was transacted, by whom and when, as well as being able to capture any additional details site requires such as heading or location, shot number or anything else. The tablet also holds a copy of all transactions, allowing operators in the magazines to view all past transactions for troubleshooting purposes. The system also clearly states quantity of each item in the magazine at all times.

Simple to use tablet interface

The tablet interface has been purposely designed to minimise data entry error while focusing on data quality and reliability. Our long history of iterative design and working closely with end users has tailored this to be a smooth, hassle-free experience. We have over 1000 explosives products from all main Australia Explosives supplier's already loaded in our system facilitating a quick start when implementing at a new site.

Flexible data capture

Any Magman task can have data capture requirements easily adjusted to meet site requirements. This includes the addition of any number of required defined data entry fields for end users, such as text boxes or lists that need to be filled out on tasks such as blast ID or receiving operator.

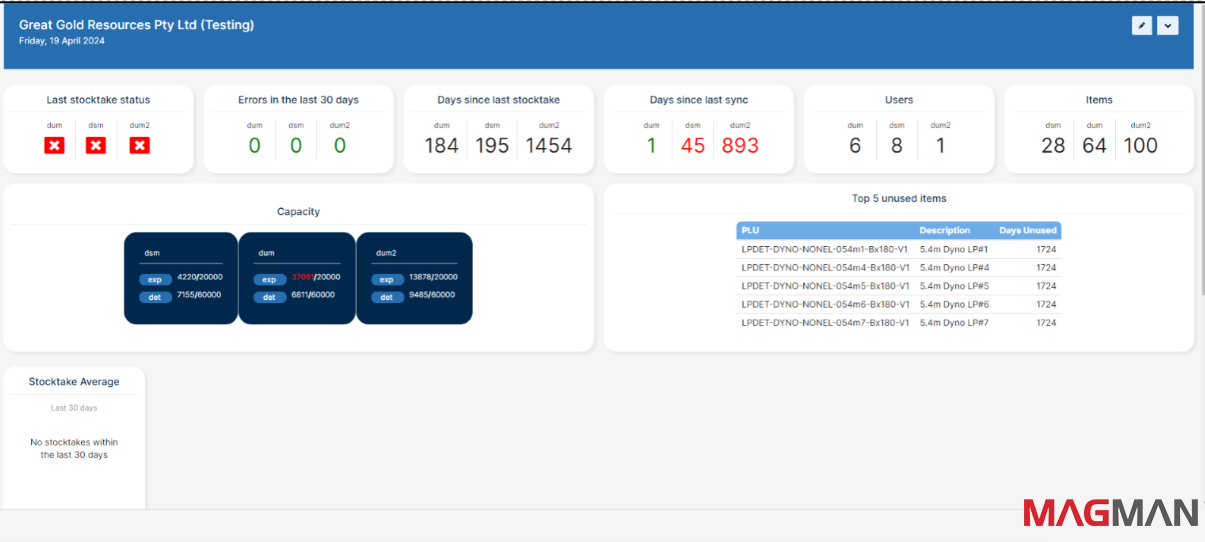

Dashboard, Excel and email reporting

The cloud website serves as a hub for a wide range of mining roles to derive insightful data. Dashboard reporting provides real-time updates on a range of compliance, inventory and safety information, including:

- Magazine compliance

- Stocktake frequency

- Days since last stocktake

- Magazine capacity

- Expiring products

- Expiring employee licenses or accreditations

- Inventory consumption rates

Additionally, each of these can have triggered exception email alerts set to allow automatic emails when any of these areas are requiring attention. For further detail, much of this information can be downloaded in flexible, on demand Excel reports or alternatively provided as scheduled emails for users who do not log in frequently.

Inventory Management

While naturally tracking inventory levels as part of the transaction process, Magman’s software has furthered inventory capabilities (outlined below).

All items can be assigned minimum stock levels and have set re-order notifications. Additionally, the system can use average consumption rates to predict when products will be out of stock and when re-ordering is required. Re-order notifications can be based on minimum level or a minimum days remaining based on recent average usage.

Planned orders can be entered into the system as well with expected delivery dates for further predictive consumption patterns. Outstanding planned orders can be notified when past delivery dates to ensure data compliance. Reporting based on expected orders can be run to ensure double ups of orders do not occur.

User Managment

Users have options for a wide range of specific permissions based on configurable role management, providing flexibility and security to all the different users on site.

Key personnel can have licenses and accreditations tied to logins, providing oversight on upcoming expiries before they lapse as well as forming a repository for documentation.

Magazine Management

Magazines and sites can be tied directly to approved storage licenses – allowing for the tracking of explosive and detonator capacities & license expiry. This information also enables overfull alerts and predictive capacities based on planned orders.

Magazines are fully customisable, with different magazines containing different items even on the same site. The ability to seamlessly transfer items to bench charging vehicles or shot utes allows for the tracking and reporting of explosives stored in vehicles and remaining items at the end of the shift.

Oversight Control

Magman supports a relationship between clients, regions, sites and magazines. Each magazine is assigned to a site, and each site can be assigned to a region. This allows for centralised services such as head office reporting to easily aggregate areas of interest to validate explosives on hand or expected use per region as well as assisting procurement to manage order flow / replenishment.

Dashboard reporting also supports views across all regions allowing for high level summaries with ability to further drill into individual site details.

Non Mining Use - Police, Government, Defence

For the last 10 years Magman has been recording and tracking mining explosives in a very strictly regulated environment. Through adherence to key legislation Magman has been able to meet the requirements for data capture, record integrity and hardware barriers.

These key features have limitless applications in a wide variety of other controlled substance or high-risk stock recording environments.

Magman’s flexibility allows it to capture inventory stock levels, quantity discrepancies and other related information for any number of different items. This makes it suitable for use in industries such as security sensitive ammonium nitrate (SSAN), explosives production chains, chemical storage such as cyanide and other sensitive industries such as firearms and fireworks.

Get in touch today and find out how Magman can digitise inventory tracking in your sensitive environment.