Blog Layout

Empowering Mining Operations: Data-Driven Solutions at Your Fingertips

Ian Jansen • Nov 03, 2023

In the fast-paced and ever-evolving world of mining, staying ahead means not only embracing change but driving it. Today, the focus is on empowering operators and supervisors with advanced tools that bring control and efficiency directly to their fingertips. This paradigm shift is epitomized by our latest innovation – a comprehensive system that enables the effortless capture of activity-based data, ranging from mining physicals to hazard reports, and even secure photo management. The impact of this leap forward is profound, particularly in the realm of productivity.

Streamlining Operations for Enhanced Productivity

The old adage 'time is money' holds exceptionally true in mining. Every minute saved in capturing and processing data translates into a significant boost in productivity. Our system eliminates the need for a control room for many routine tasks. Operators and supervisors can now input and access critical data on-site, reducing delays and increasing the time available for core mining activities. This efficiency gain is not just a step forward; it's a leap into a new era of mining operation.

Harnessing Data for Smarter Decisions

The role of data analysis and machine learning in this transformation cannot be overstated. By leveraging these technologies, our system doesn't just collect data; it turns it into actionable insights. Whether it's optimizing the use of machinery, adjusting workforce schedules, or predicting maintenance needs, machine learning algorithms process vast amounts of data to help supervisors make smarter, faster decisions.

Safety and Productivity: Two Sides of the Same Coin

The old adage 'time is money' holds exceptionally true in mining. Every minute saved in capturing and processing data translates into a significant boost in productivity. Our system eliminates the need for a control room for many routine tasks. Operators and supervisors can now input and access critical data on-site, reducing delays and increasing the time available for core mining activities. This efficiency gain is not just a step forward; it's a leap into a new era of mining operation.

Harnessing Data for Smarter Decisions

The role of data analysis and machine learning in this transformation cannot be overstated. By leveraging these technologies, our system doesn't just collect data; it turns it into actionable insights. Whether it's optimizing the use of machinery, adjusting workforce schedules, or predicting maintenance needs, machine learning algorithms process vast amounts of data to help supervisors make smarter, faster decisions.

Safety and Productivity: Two Sides of the Same Coin

While our focus here is on productivity, it's important to recognize that safety and productivity in the mining industry are deeply interconnected. A safer operation is invariably a more productive one. Our system's ability to quickly capture and report hazards means that safety issues can be addressed more rapidly and effectively, reducing downtime and ensuring a smoother operational flow.

In conclusion, by empowering operators and supervisors with the right tools and technologies, we're not just enhancing productivity; we're shaping a smarter, safer, and more efficient future in mining. This is just the beginning of a journey towards a more data-driven and responsive mining industry, where every decision is empowered by real-time insights.

06 May, 2024

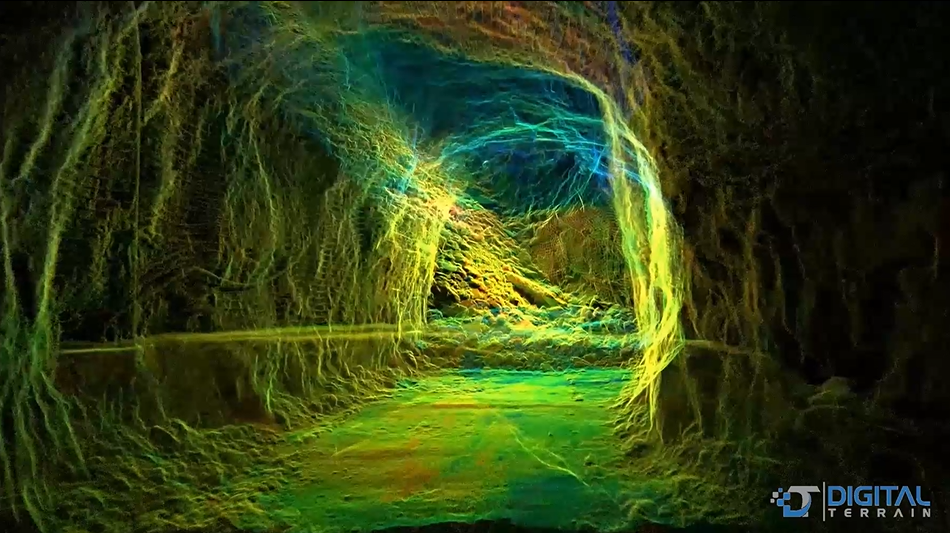

In the world of underground mining, inaccessible areas such as stopes and ore passes are crucial areas that directly determine the shift and monthly productivity. Cavity Monitoring Systems (CMS) provide limited visibility into these dangerous areas but are constrained by access. Digital Terrain continue to pioneer Autonomous LiDAR enabled drone technology with solutions that offer rich capabilities in mapping, monitoring, and managing underground environments. Key benefits in underground mining include: 1. Precise 3D Mapping: LiDAR technology enables high-resolution 3D mapping of underground environments with remarkable accuracy. By emitting laser pulses and measuring the time it takes for them to return, LiDAR scanners can create detailed point clouds that accurately represent the terrain, infrastructure, and geological features of underground workings, including stopes and inaccessible areas. 2. Enhanced Safety: One of the most significant benefits of Autonomous Drone technology in underground mining is its contribution to safety. By operating within the protective barricades and barriers comprehensive data on the conditions of underground workings, LiDAR derived data helps identify potential hazards such as unstable ground, roof collapses, or hangups and blockages. This allows mining operators to take proactive measures to mitigate risks and ensure the safety of employees. 3. Improved Planning and Design: LiDAR-generated 3D maps facilitate better planning and design of underground mining operations. By accurately capturing the geometry and topography of stopes and voids, mining engineers can optimize the layout of infrastructure, plan drilling and blasting activities more effectively, and minimize waste generation. This leads to increased operational efficiency and reduced costs. 4. Monitoring and Management: LiDAR enabled drones enables continuous monitoring of underground environments, providing valuable insights into ground movement, rock stability, and infrastructure integrity. By comparing successive LiDAR scans over time, mining operators can detect changes in the underground environment, assess the effectiveness of ground support measures, and identify areas requiring maintenance or remediation. 5. Remote Inspection and Exploration: Drones integrated with LiDAR technology offers a non-intrusive means of inspection and exploration. By deploying LiDAR-equipped drones or robotic platforms, mining operators can autonomously survey inaccessible areas, gather valuable data, and make informed decisions where only a few short years ago it was near impossible to gain insights into these underground areas. 6. Augmented services vs Do it yourself (DIY) Most mines have already invested in drone and LiDAR technology to some extent, but have been disappointed with the results or have suffered lost and damaged equipment. There are many reasons for this including Personnel changes mean constant re-training Operators only gain limited and site-specific experience. This makes them unprepared for difficult scenarios that might develop. Infrequent use almost always results in loss and damage of expensive equipment Collecting the data is only half the job. Processing the data collected requires specialist skillsets. Processing and interpreting collected data is extremely heavy on compute and is very data intensive because of the sheer size of datasets. Processing turnaround is crucial. Operators often do not have sufficient time to learn and experiment with processing software, techniques and settings for optimal results – all with time sensitivity to inform operational decisions. Historical data collected over time is lost or not managed correctly Specialist shaft, lighting and other sensor attachments are not easily available but are critical for success Digital Terrain Digital Terrain have solutions that replace or augment existing capabilities for capturing, processing, analysis and reporting. We also offer onsite instruction and training where customers seek to build their own expertise. > Enjoy the sample video of our capabilities and contact David Juany for any comments, questions, or service information

12 Mar, 2024

Solving explosive management and compliance issues in mining and regulated industries The industry is a bustling sector of ideas, products, services that are intended to help make the most of the mining value chain. It's often tempting for organisations that sell into this sector to focus on the allure of features. Anything from the sleek intrinsically safe tablet to the functionalities of a software program that manages resource specific requirements. Features are flaunted as badges of innovation and superiority – yet in this there lies a profound oversight: the neglect of the fundamental question – what problems do these features solve? Our Chief Operating Officer – Ian Jansen encouraged our team to think about the problems we solve for our customers and to retain the essence of why people seek out our Magman products in the first place. Word of mouth has been a wonderful tool that has allowed us to acquire over 70 mine sites globally but is only one thread of challenges, desires, and aspirations of our customers. In highly regulated industries every organisation grapples with a mix of compliance, operational and unique site-specific problems. It is within the context of these challenges that Magman (acquired by Digital Terrain in 2023) is applying the lens of true value and embarking on our next round of problems to solve. This led us to summarise what problems we solve today, and what we do today – a digital no-nonsense product, built by miners, for miners to help with the management of a magazine for explosives. Making sure that compliance is met, while being easy to use; and we’ve been doing it for over 10 years, so we know a thing or two about what works and what doesn't. Make it easy : We make it easy to replace paper record keeping in a magazine with legislatively compliant, certified, intrinsically safe tablets and specialist software. Easier said than done because we’ve seen many complex problems to the simple problem of replacing paper records. Reduce Errors : We reduce the number of errors, with no need to transcribe into error prone spreadsheets with formulas. It’s all done for you. Automatic notification and escalation of errors. The cost of shutting down the operation to resolve an error is enormous. Correcting typos on the go is handy and helps this too. Improve Accuracy : Large, simplified buttons backed by best practice user processes helps with the repetitive nature of data capture for explosives movement Efficient blast designs or stope firings : Prevents busy operators from needing to fill out entire takes. This improves speed and efficiency akin to a recipe process. Elevating governance and risk management : Unmissable notifications that highlighting on stock discrepancies keeps the magazine in check. Peace of mind with notifications that enable 24/7/365 compliance and governance needs with change logs and transaction history for investigation audit trails. Ease of Reporting : Integrated reporting or export of data to excel, with dashboarding and API options.

Simbio Core Suite

Simbio Regulated Materials

Maintenance Management

Simbio IOT

Drone and Digitisation

Simbio Asset Monitoring

Location intelligence and proximity

Simbio Integration

Company

© 2024

Digital Terrain. All Rights Reserved